Unlocking Factory Load Growth Under Contracted Grid Limits in Spain

Project Overview

In response to constrained transformer capacity and increasing industrial load demand, FFD POWER deployed a 250kW/522kWh BESS in Spain to provide capacity relief through EMS-controlled peak support and precise grid import limiting. The solution bridges the gap between the factory’s growing load demand and the limited transformer/grid capacity available on site. By enforcing a grid import cap and dispatching storage in real time, the system prevents transformer overload, enables full load operation, and improves energy utilization when on-site PV is available.

Project Background

The customer operates a factory in Spain where the total site load has grown beyond the contracted grid capacity and the rating of the on-site transformer. Upgrading the transformer or increasing the contracted capacity can be time-consuming and capital-intensive. As a result, the factory faced operational constraints, including the inability to start all loads simultaneously without exceeding the allowed import limit. The customer also deployed on-site PV to supplement renewable energy supply, creating additional opportunities to reduce grid dependence. The project required an energy storage solution that could provide fast peak support, keep grid import within the allowed limit, and coordinate PV and storage to improve overall site operation.

Project Challenge

- Transformer / Contracted Capacity Constraint: Total factory load can exceed the permitted import limit, risking transformer overload and penalties.

- Load Growth Without Infrastructure Upgrade: The site needed to unlock additional usable capacity quickly without immediate transformer replacement.

- EMS Precision Control: The EMS must enforce power limits and coordinate charging/discharging to maintain stable operation and available headroom.

FFD POWER Solution

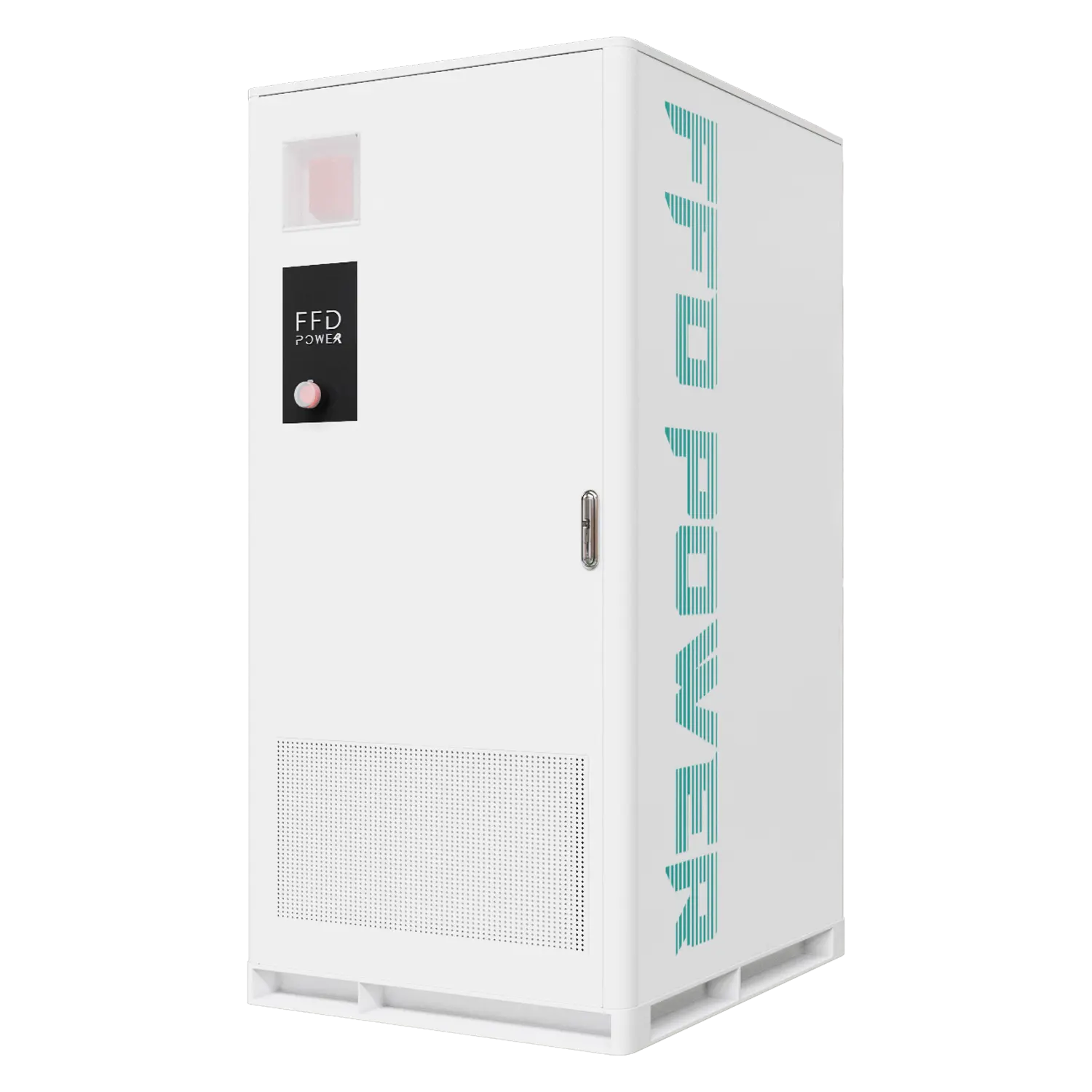

FFD POWER delivered a 250kW/522kWh behind-the-meter BESS with PCS and EMS control to provide transformer capacity relief. The EMS continuously monitors site load and grid import, enforcing a defined import cap aligned with the transformer and contracted capacity. When site demand approaches or exceeds this limit, the PCS discharges the BESS to supply the difference, preventing overload and allowing the factory to run additional equipment. When PV generation is available, PV supplies the load first and can charge the BESS with EMS-managed power limits, improving renewable utilization and reducing dependence on the grid.

System Specifications

- PV installed : On-site PV to supplement factory supply

- BESS POWER : 250 KW

- BESS capacity : 522 KWH

- Product used : Galaxy261L all-in-one Cabinet (125kW/261kWh Unit) * 2 + EMS (behind-the-meter)

- Architecture: Transformer Capacity Relief via Grid Import Limiting + Peak Support (PV-Assisted Charging)

Operational Logic: Transformer Capacity Relief with EMS Import Cap

The EMS controls the PCS to keep grid import within the contracted/transformer limit while enabling additional load operation:

- Grid Import Limiting: The EMS sets an import cap aligned with the transformer and contracted capacity. When grid import reaches the cap, the BESS discharges to cover incremental load demand and prevent overload.

- Peak Support for Load Start-Up and Operation: The PCS provides fast response power to support motor starts and peak load events, allowing the factory to operate more equipment without exceeding grid constraints.

- PV-Assisted Energy Management: PV supplies the load first and charges the BESS with EMS-managed limits when surplus exists. The EMS also manages SOC to ensure headroom is reserved for capacity relief when needed.