Peak Shaving and Fast-Charging Load Support on a 400V LV Bus in Morocco

Project Overview

BESS for Factory Microgrid in Myanmar showcases how a 250kW/522kWh cabinet battery energy storage system can stabilize and optimize a microgrid supplying a factory dormitory complex. In environments where grid power can be weak or intermittent, the BESS provides fast load balancing, supports seamless transitions, and improves power quality for residential and facility loads. The EMS coordinates load-following dispatch, reserve management, and generator/PV coordination to keep supply reliable while reducing fuel and operating costs.

Project Background

Factory dormitories operate like small communities: lighting, HVAC, canteens, water pumps, and IT loads create daily peaks, while night-time demand remains significant. In Myanmar and similar developing-grid regions, voltage fluctuations and outages can disrupt operations and living conditions, and diesel generation is often used as a backup or primary source. A BESS integrated into a microgrid enables higher stability and efficiency by smoothing fast load changes, providing ride-through during switching, and allowing generators to run at more efficient operating points.

Project Challenge

- Weak/Unreliable Supply: Maintain stable voltage and frequency for dormitory loads despite grid disturbances or source switching events.

- Generator Efficiency and Wear: Reduce frequent generator start/stop and prevent low-load operation by using the BESS for short peaks and transitions.

- Operational Reserve and Safety: Maintain SOC reserve for outages and ensure coordinated protection across sources to avoid blackouts and nuisance trips.

FFD POWER Solution

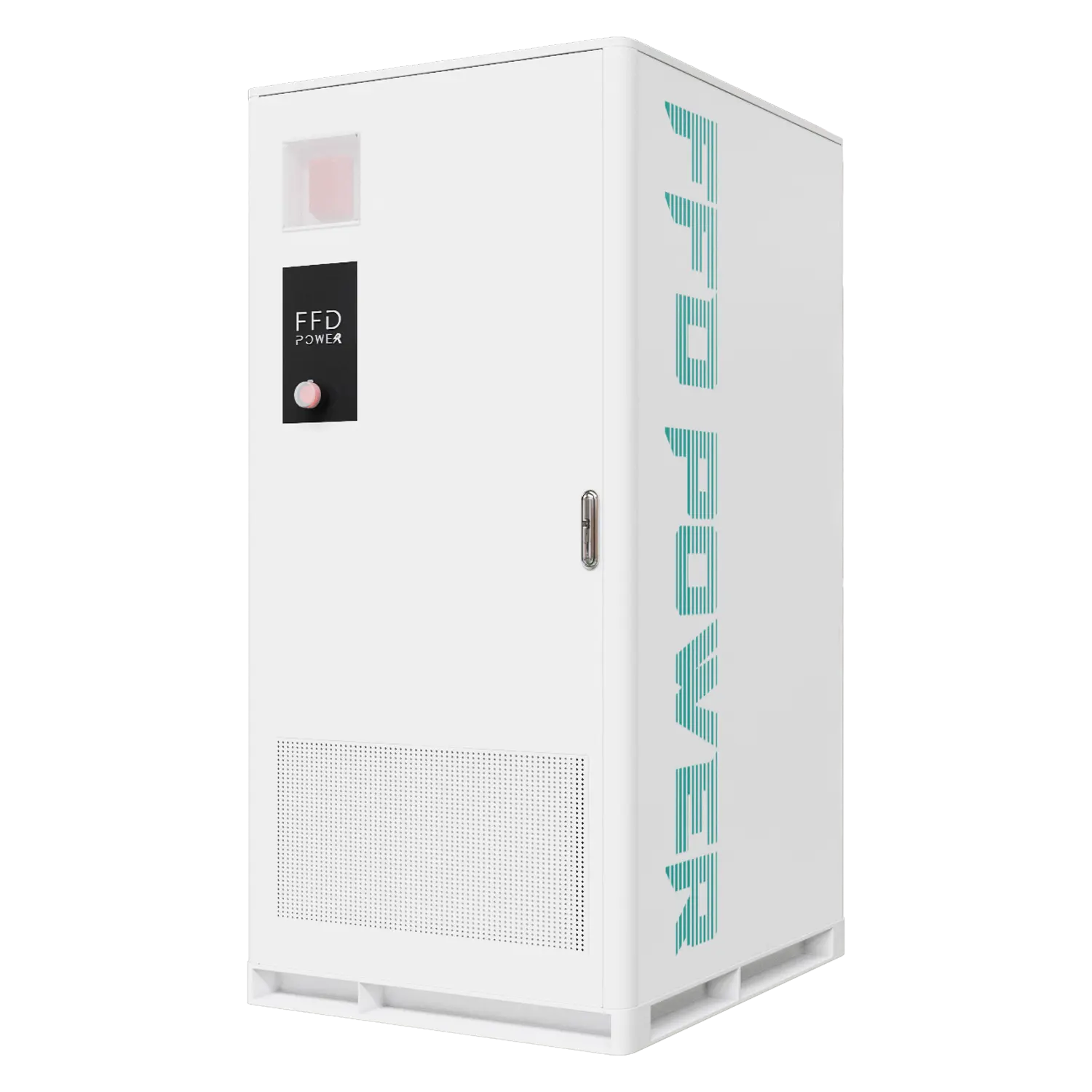

FFD POWER deployed a 250kW/522kWh cabinet BESS as a core flexibility asset within the dormitory microgrid. The EMS provides load-following control: the PCS compensates rapid demand fluctuations and supports peak supply, while a reserve policy guarantees emergency headroom. When used with diesel generation, the EMS implements generator-support logic that reduces cycling, improves fuel efficiency, and stabilizes the microgrid during transitions.

System Specifications

- BESS POWER : 250 KW

- BESS capacity : 522 KWH

- Product used : Galaxy 261L Cabinet-type all-in-one BESS * 2

- Application : Microgrid stabilization (factory dormitory)

- Architecture: EMS with load-following + reserve SOC + generator support / smooth transfer

Operational Logic: Load Following + Reserve + Generator Support

The EMS logic prioritizes microgrid stability and continuity while optimizing operating cost:

- Load-Following Dispatch: adjusts BESS charge/discharge to balance fast load changes and maintain stable microgrid power.

- Reserve SOC Management: maintains a minimum SOC for outage ride-through and transition support; limits discretionary discharge below reserve.

- Generator Support Strategy: supplies short peaks and absorbs transients to avoid generator overload/underload, reducing starts and improving fuel efficiency.