Lowering Cold-Chain OPEX with TOU Strategy — in an Israeli Cold Storage Facility

Project Overview

BESS for Industrial TOU Arbitrage in Israeli shows how a 500kW/1075kWh cabinet battery energy storage system can reduce electricity costs for a refrigeration-intensive site by shifting energy consumption across high and low tariff periods. Cold storage facilities typically operate 24/7 with large compressor loads, making them highly exposed to time-of-use (TOU) price spreads and demand charges. By charging during off-peak periods and discharging during peak windows, the BESS lowers the site’s effective energy cost while also shaving short demand spikes. The EMS coordinates TOU scheduling, SOC targeting, and demand-limiting to keep operations stable and refrigeration uninterrupted.

Project Background

Cold storage is an energy-intensive industry where refrigeration systems run continuously to maintain temperature and product quality. In Israel, industrial electricity tariffs can create significant cost differences between peak and off-peak hours, and maximum demand can dominate the monthly bill. At the same time, refrigeration loads can ramp quickly as compressors cycle or as doors open and close, creating short peaks and stressing the power connection. A behind-the-meter BESS enables an effective cost-control tool: it time-shifts energy to reduce peak purchases and caps demand without impacting cold-chain continuity.

Project Challenge

- 24/7 Critical Load: Ensure refrigeration continuity while implementing charging/discharging schedules.

- Tariff & Demand Exposure: Capture TOU spreads and reduce demand peaks that increase capacity charges.

- Operational Safety & Efficiency: Prevent over-cycling and manage SOC/temperature limits while maintaining sufficient reserve for contingencies.

FFD POWER Solution

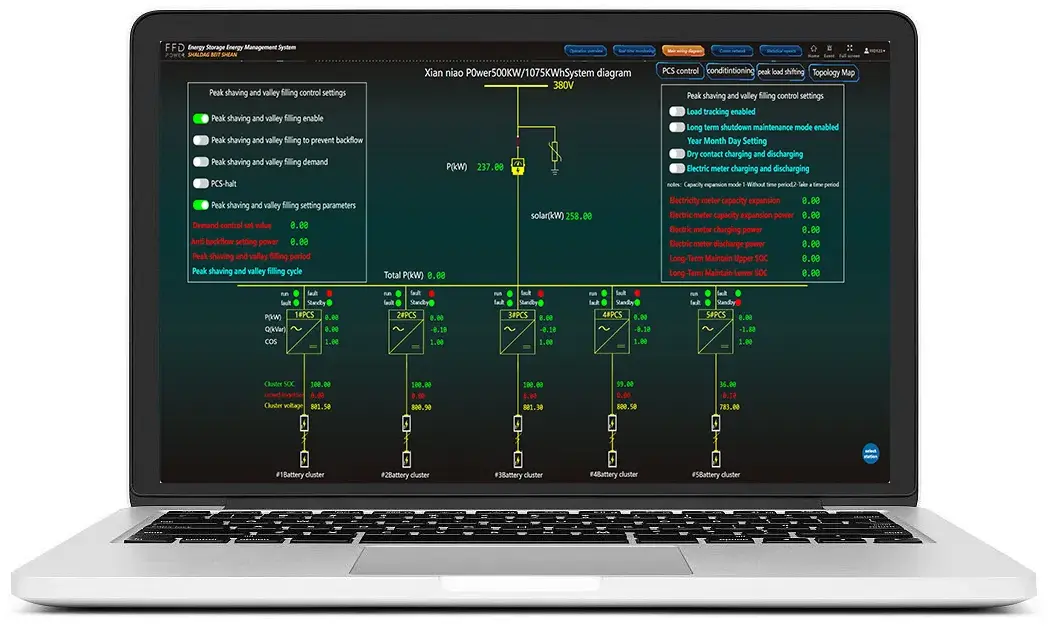

FFD POWER deployed a 500kW/1075kWh cabinet BESS integrated with an EMS configured for industrial TOU arbitrage and demand control. The EMS schedules charging during low-tariff windows and discharging during peak tariff periods, while enforcing a demand cap to shave short spikes from compressor cycling. SOC targets and protection constraints maintain battery health and guarantee operational readiness, ensuring savings without compromising the facility’s cold-chain requirements.

System Specifications

- BESS POWER : 500 KW

- BESS capacity : 1075 KWH

- Product used : Galaxy 215 Cabinet-type all-in-one BESS * 5

- Application : Industrial TOU arbitrage + demand peak shaving (cold storage)

- Architecture: EMS with TOU schedule + demand cap + SOC target window & reserve

Operational Logic: TOU Scheduling + Demand Cap

The EMS logic combines tariff-driven scheduling with real-time demand control:

- Off-Peak Charging: charges during low-tariff periods, within SOC and power limits, to store low-cost energy.

- Peak Discharge for Arbitrage: discharges during peak tariff windows to reduce high-cost grid purchases while prioritizing refrigeration continuity.

- Demand Peak Shaving Overlay: enforces a site demand cap; when compressor cycling causes load spikes, the BESS discharges to keep grid import below the cap.