News

Industrial Lithium-Ion UPS: Online Double Conversion Power Protection for the Next Decade

- January 27, 2026

Industrial lithium-ion UPS refers to a high-power UPS solution—typically above 100 kW and scalable up to around 3 MW—designed for mission-critical industrial loads such as data center server infrastructure, PLC-driven manufacturing lines, medical facilities, broadcast systems and mission-critical networking.

In high-power industrial environments, even millisecond-level disturbances—voltage sags, harmonics, or micro-outages—can trip sensitive equipment and cascade into downtime. That’s why the preferred architecture is the online (double-conversion) UPS: it continuously converts AC→DC→AC to deliver clean, regulated power and provides a true 0 ms, no-break transfer during grid events. Paired with lithium-ion batteries, this platform also enables longer backup runtime with stable discharge performance, making it a robust, always-on power conditioning and protection system rather than a simple “backup battery.”

A brief history of UPS development: from rotating machines to modern power electronics

UPS systems did not start as compact static cabinets. Early UPS approaches leaned heavily on rotating machines, flywheels, and motor-generator concepts to ride through short interruptions. By the 1960s, larger-capacity systems appeared (e.g., hundreds of kVA), and the industry began shifting toward static UPS architectures enabled by advancing power electronics (e.g., thyristor-based inverter solutions) to reduce the noise, vibration, maintenance, and footprint constraints associated with motor-generator approaches.

Over the following decades, UPS adoption expanded far beyond niche critical facilities. What began largely as small systems in the single-digit kVA range for IT and control loads has already evolved into industrial-scale deployments above 100 kW, with multi-module and parallel architectures routinely scaling into the MW class for data centers, manufacturing, healthcare, and broadcast infrastructure. In parallel, UPS battery practice standardized around lead-acid variants (including VRLA) due to cost and familiarity. But over time, operators discovered the operational burden of batteries—maintenance overhead, replacement cycles, floor space, and thermal sensitivity—creating the opening for a new battery platform: lithiumion.

UPS topologies in practice: standby vs line-interactive vs online

Most UPS discussions eventually converge on topology, because topology determines what the load “sees” during real-world grid disturbances.

Common categories include:

- Standby (offline): load normally fed directly from utility; UPS switches on when utility fails.

- Line-interactive: inverter assists and regulates; typically improved efficiency and cost vs online, but less isolation.

- Online (double conversion): load is continuously powered through the inverter, providing maximum conditioning and isolation.

This is a standard taxonomy across UPS references, and online UPS is explicitly associated with the double conversion method.

For the rest of this article, we focus on the topology most aligned with “no-compromise” power quality: lithium ion online UPS (double conversion lithium UPS).

What is double conversion (online) UPS—and why it matters

A double conversion online UPS continuously converts:

- AC → DC (rectifier stage), then

- DC → AC (inverter stage) to feed the critical load.

Because the inverter is always supplying the load, disturbances on the input side (sags, surges, noise, frequency instability) are not directly passed through.

Key advantages of online double conversion UPS

- Best-in-class power quality: tightly regulated voltage and frequency at the output.

- 0 millisecond transfer time: the inverter is already online; battery supports the DC bus immediately on outage.

- Isolation from grid events: helps protect sensitive electronics from sags/surges/harmonics.

- Predictable behavior under abnormal utility: brownouts, generator mode, unstable frequency conditions.

This is why “online UPS” is often the default for data centers, semiconductor processes, hospitals, and any application where a momentary disturbance can become a business outage.

Why lithium ion UPS is replacing lead-acid in critical facilities

The battery is the energy buffer that converts “power quality” into “power continuity.” Historically, VRLA was the default. The trend now is clear: lithium-ion UPS batteries are increasingly adopted because they improve lifecycle economics and physical deployment constraints—especially for space-constrained, high-density facilities.

Lifecycle and replacement intervals

The UPS industry summarizes a common planning reality: lithium-ion batteries often last 10–15 years, while lead-acid batteries may require replacement every 3–5 years, changing total cost of ownership and operational disruption.

Footprint and weight: the data center driver

Experts explains lithium-ion’s higher energy density in UPS contexts, noting a ~50% to 75% footprint reduction compared with VRLA in many implementations—freeing space for IT equipment or reducing facility construction costs.

Efficiency, recharge, and deeper discharge tolerance

Experts also emphasizes faster recharge and higher efficiency behavior for lithium-ion in UPS use, improving resilience during repeated disturbances and high-load conditions.

Built-in battery management and improved monitoring

One of the most underappreciated differences is architectural: lithium-ion systems are designed with battery management capabilities at cell/module/cabinet levels, enabling more sophisticated health data and more predictable performance.

Thermal behavior and operating environment

Another seldom noted difference is that lithium-ion can operate at higher temperatures without sacrificing battery life in the same way as VRLA, and highlights a commonly-cited VRLA challenge: battery life can degrade sharply with heat rise.

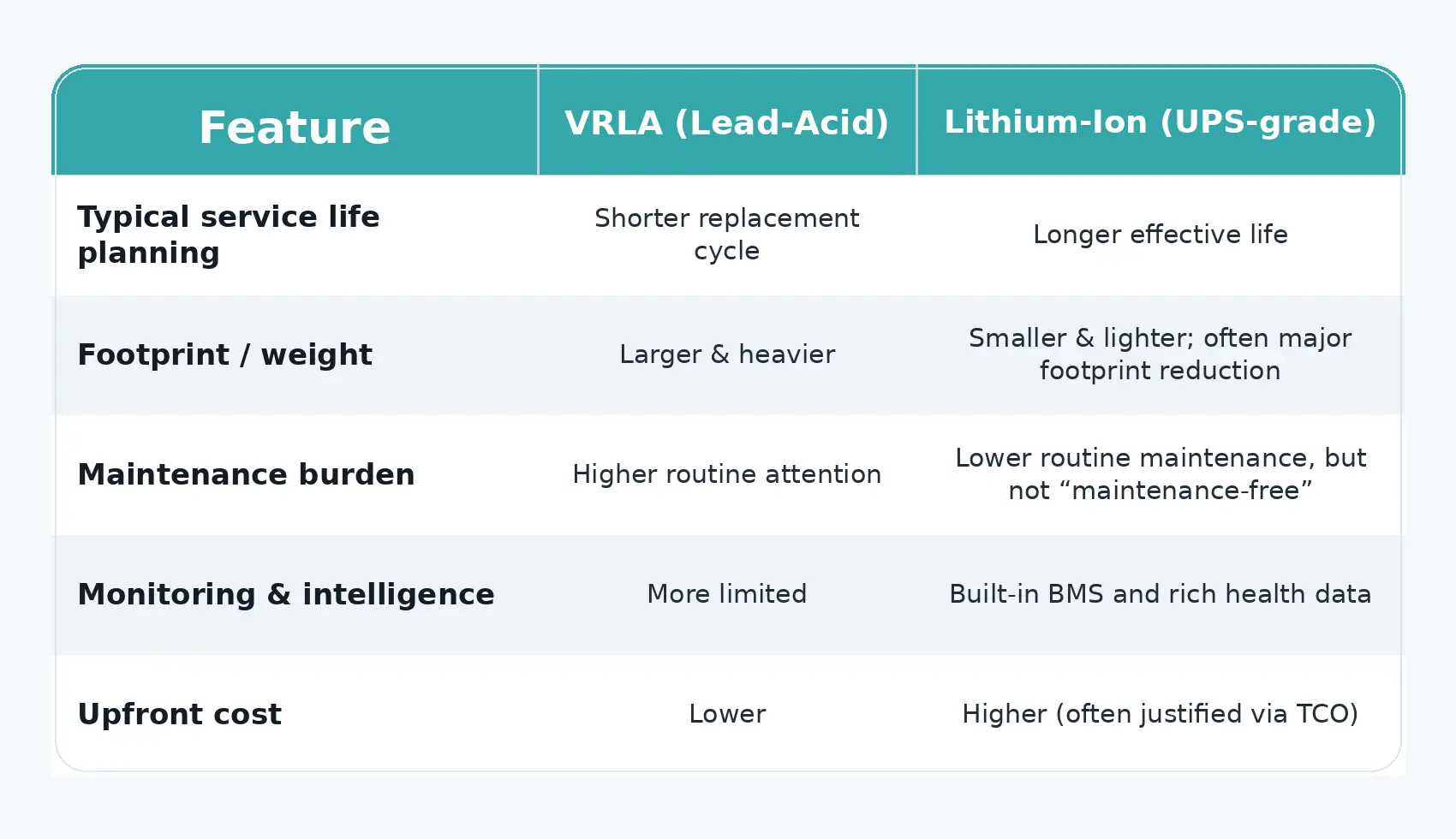

Lithium-ion vs VRLA in UPS applications: practical comparison

Below is a practical, buyer-oriented interpretation (not a lab spec sheet). It reflects the qualitative comparisons found in industry guidance.

Bottom line: the business case is increasingly framed as TCO + space + operational risk rather than initial battery price.

Safety: what “UPS-grade lithium” means in real deployments

Decision-makers often conflate lithium-ion incidents in consumer electronics with industrial UPS installations. Experts explicitly caution against that confusion and explains that data-center / UPS applications typically involve different design priorities and incorporate multi-layered protections, extensive management systems, and fail-safe mechanisms.

Important safety-oriented considerations include:

- Choose the right chemistry for the application. It is noted that handheld devices often use LCO, while stationary/UPS contexts commonly use alternatives such as LFP, NMC, LMO, which have different performance and safety trade-offs.

- Standards and codes matter. UL standards—and the NFPA Fire Code’s reference to UL 1973 for lithium-ion batteries in data center applications—show how compliance frameworks have matured, enabling broader adoption.

- Qualified installation and maintenance. Industry best practice is to use battery systems that are approved and supported by the UPS manufacturer, and to have commissioning and ongoing monitoring carried out by trained professionals. Lithium-ion still requires correct procedures and discipline—even if routine maintenance demands are reduced.

- Material profile and facility integration. From an industry perspective, lithium-ion UPS batteries typically avoid heavy metals such as mercury, lead, and cadmium, and are increasingly designed for seamless integration with facility monitoring platforms (e.g., BMS/DCIM) for alarms, status, and health reporting.

What to look for in a industrial lithium ion online UPS (buyer checklist)

When specifying a double conversion lithium UPS, a practical checklist is more useful than marketing adjectives.

- Topology: confirm it is true online double conversion (not “online” as a loose term).

- Power rating and scalability: single unit sizing plus parallel/N+1 planning for critical loads.

- Battery architecture: UPS-grade lithium cabinets with BMS, clear runtime assumptions, and service plan.

- Monitoring & communications: SNMP/Modbus integration into DCIM/BMS/SCADA environments.

- Safety compliance approach: alignment with relevant standards and facility fire/electrical code requirements.

- Lifecycle economics: battery replacement intervals, maintenance labor, and footprint value—especially in high-rent white space.

FFD POWER: industrial lithium-ion online UPS solutions designed for modern critical loads

FFD POWER’s UPS roadmap aligns with where the market is already moving: online double conversion UPS architecture paired with lithium-ion batteries, targeting modern critical facilities that need both continuous conditioning and high availability.

Example: 125 kW / 500 kW lithium-ion online UPS solutions (typical deployment concept)

125 kW and 500 kW online UPS systems are commonly used as scalable building blocks in:

- data center electrical rooms (edge sites, modular DCs),

- industrial control and automation lines,

- critical telecom and network nodes,

- critical infrastructure auxiliary power.

Scalable architecture up to 3 MW

For higher power levels, these UPS blocks can be deployed in parallel (with N or N+1 redundancy) and expanded from hundreds of kW to multi-MW capacity—up to 3 MW—to match the growth path of large data halls, manufacturing campuses, and critical facilities.

In a typical design approach:

- The online (double conversion) UPS supplies a clean and stable AC output continuously (rectifier + inverter path), ensuring 0 ms no-break transfer during grid disturbances.

- A lithium battery cabinet with BMS provides fast, predictable discharge performance and supports the required backup runtime profile.

- Monitoring is integrated into the site’s management systems so battery health, alarms, and operating status can be supervised centrally.

If your project requires a specific runtime, redundancy model (N, N+1), or integration into an existing LV/MV distribution scheme, FFD POWER can provide a project-level configuration package (single-line concept, UPS/battery sizing logic, and monitoring interface definition).

Summary

- A lithium-ion UPS combines a modern UPS platform with lithium-ion batteries to deliver power continuity and improved lifecycle economics for critical facilities.

- Industrial lithium-ion UPS has evolved beyond small kVA-class systems into high-power solutions above 100 kW, reflecting the rapid growth of critical-load demand in data centers, industrial automation, telecom, and infrastructure.

- The highest-protection topology is the online (double conversion) UPS, which continuously converts AC→DC→AC to isolate the load from grid disturbances, deliver clean regulated power, and enable 0 ms no-break transfer to battery during input anomalies.

- Compared with VRLA, lithium-ion UPS batteries typically offer longer service life, lower maintenance, and significant footprint reduction—often a decisive advantage in data centers and space-constrained sites.

- UPS-grade lithium deployments depend on BMS-enabled monitoring, appropriate chemistry and thermal design, and compliance with applicable safety standards and qualified procedures—materially different from consumer lithium use cases.

- FFD POWER focuses on industrial lithium-ion online UPS offerings, including 125 kW-class solutions and 500 kW-class solutions scalable up to 3 MW, supporting critical loads with clean power, high availability, and a modular expansion path.