Diesel Hybrid Microgrid with BESS (Minimum Loading + Sweet Spot Strategy)

Diesel Hybrid Microgrid with BESS is a proven way to cut fuel burn and improve stability by using the battery to keep the genset out of inefficient low-load operation and to absorb fast load swings.

This article focuses on minimum loading discipline, the ‘sweet spot’ strategy (often near ~70% rated load), and how EMS priorities translate into measurable operational ROI.

Why diesel gensets waste fuel at low load

A genset has baseline fuel use just to keep the engine running at rated speed, plus incremental fuel as electrical load increases. At low load, that baseline dominates—so liters per kWh is worse than at mid/high load.

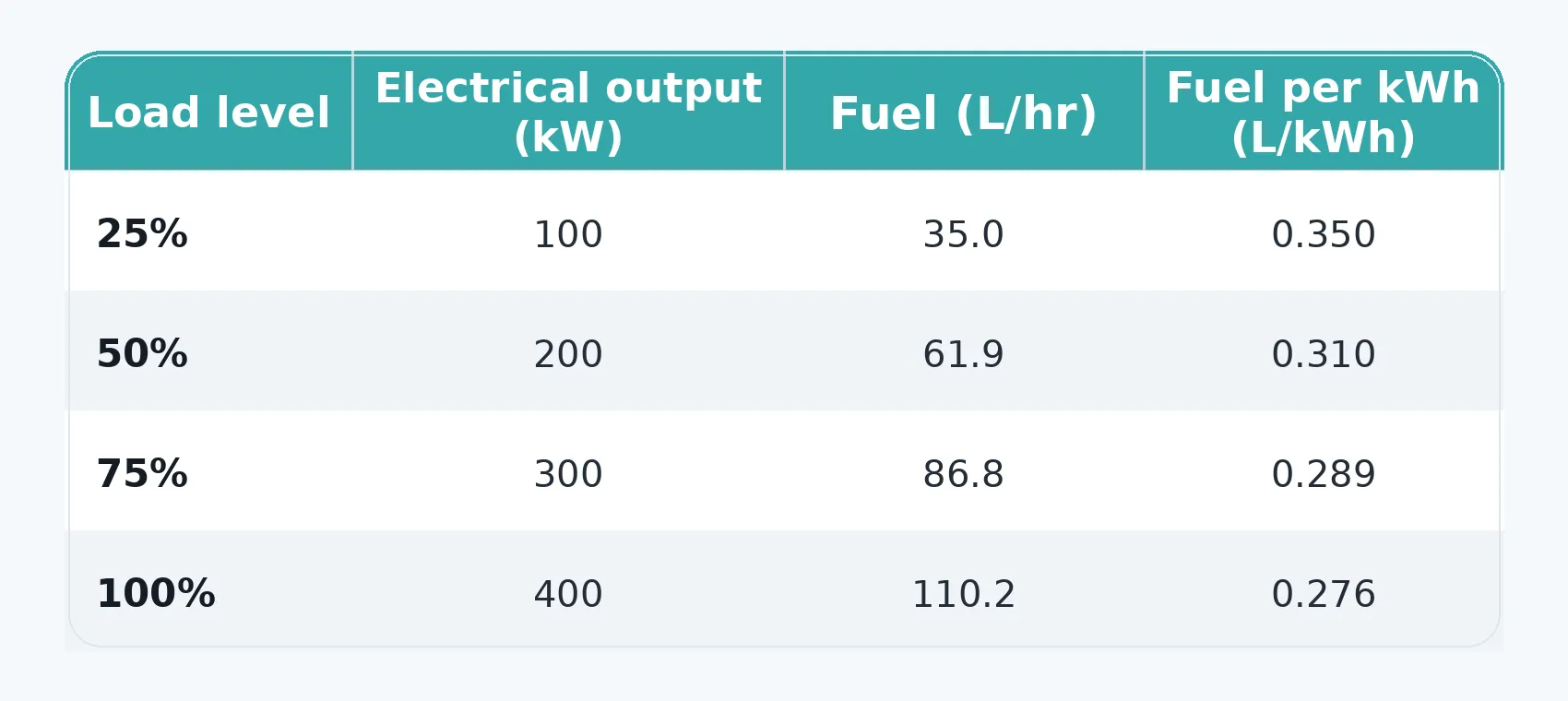

A practical curve with source

To illustrate, Caterpillar’s Cat® C15 diesel generator datasheet provides fuel consumption at 25/50/75/100% load. Using the 400 ekW column, fuel consumption is 35.0, 61.9, 86.8, and 110.2 L/hr respectively; dividing by kW output shows liters per kWh improves as load increases. This is why minimum-loading control matters in practice.

Minimum loading: what to enforce and why

Many operators treat sustained low-load operation (often discussed around the ~30–40% region, depending on engine and site conditions) as undesirable because it worsens fuel per kWh and can reduce combustion temperature margins. In hybrid microgrids, the battery is the tool that makes minimum-loading discipline achievable without wasting power.

If load is too low: charge the battery (or curtail PV) so the genset stays in a healthier band.

If load steps up: discharge the battery so the genset avoids fast transients and overload risk.

If PV fluctuates: the battery buffers ramps so the genset sees a smoother net load.

“Our 261kWh/125kW BESS Cabinet is engineered to make C&I energy storage simpler to deploy, easier to operate, and faster to scale—turning tariff complexity into predictable savings”

The ‘sweet spot’ strategy (often near ~70% rated load)

In many projects, the goal is not to run at 100% all day. Instead, the EMS targets a stable operating band where the genset is efficient and thermally healthy, while leaving margin for sudden load increases. A ~70% target is a common, practical compromise: efficient per kWh, stable, and not pushing the engine to its limits continuously.

How BESS + EMS executes the strategy (rule-based)

- Define genset target band (e.g., 60–80% rated) and a minimum loading floor.

- Define SOC reserve for contingencies and for critical-load continuity.

- When net load < minimum floor: charge BESS (or reduce PV export) to raise genset loading.

- When net load > upper band or during step events: discharge BESS to cap genset loading and smooth ramps.

- Start/stop policy: start genset only when sustained deficit exists or SOC approaches reserve; stop when stable and SOC is recovered.

Where the ROI actually comes from

- Lower liters per kWh at the operating point you actually run most hours.

- Fewer nuisance trips because the site bus sees fewer fast swings.

- Better PV utilization: PV doesn’t have to be curtailed just to protect the genset from minimum-load issues.

- Reduced downtime risk for industrial processes sensitive to frequency/voltage events.

Design notes for real sites (motors, compressors, pumps)

Inductive loads make the case stronger: sudden starts and torque changes are exactly where a battery provides fast response while the genset ramps smoothly. If PF can dip toward 0.8, ensure the inverter and switching are sized with kVA headroom and that EMS logic accounts for reactive behavior.

FFD POWER Note

FFD POWER’s hybrid microgrid EMS can enforce genset minimum-loading and a target operating band by charging/discharging the BESS in real time, while maintaining SOC reserve for contingencies and critical loads.

In fully hybrid systems (grid + PV + genset + BESS), this strategy improves both fuel economics and power stability without turning the site into an over-complicated control project.

FAQs

It’s a system where a battery and EMS coordinate with a diesel generator (often alongside PV and grid) to stabilize the site bus and optimize genset operation for fuel and reliability.

Because baseline fuel consumption becomes a larger share of output, so fuel per kWh worsens; sustained low-load operation can also be operationally undesirable depending on engine and site conditions.

A mid-high band often balances fuel efficiency, thermal health, and headroom for fast load changes. It’s a practical target for continuous operation rather than pushing to full load.

By charging when net load is low (keeping genset load in an efficient band) and discharging during peaks/steps so the genset avoids inefficient swings.

PV helps reduce energy that must come from diesel, but PV variability can hurt stability unless the battery buffers ramps and EMS enforces minimum-loading discipline.

FFD POWER Annual Gala Night: A Celebration of People, Performance, and Shared Vision

Company Event FFD POWER Annual Gala Night: A Celebration of People, Performance, and Shared Vision Last night, FFD POWER successfully hosted its Annual Gala Night,

Keeping Retail Operations Running during Grid Events — BESS for Supermarket Backup Power in Ukraine

Keeping Retail Operations Running during Grid Events — in Ukraine Project Overview BESS for Supermarket Backup Power in Ukraine demonstrates how a 100kW/261kWh cabinet battery

Turning Solar Surplus into On-Site Value — BESS for PV Self-Consumption in Israel

Turning Solar Surplus into On-Site Value — in Israel Project Overview BESS for PV Self-Consumption in Israel demonstrates how a 125kW/261kWh cabinet battery energy storage

Production Growth without Immediate Grid Upgrade — BESS for Transformer Capacity Expansion in Spain

Production Growth without Immediate Grid Upgrade — in Spain Project Overview BESS for Transformer Capacity Expansion in Spain demonstrates how a 250kW/522kWh cabinet battery energy

Lowering Cold-Chain OPEX with TOU Strategy — BESS for Industrial TOU Arbitrage in an Israeli Cold Storage Facility

Lowering Cold-Chain OPEX with TOU Strategy — in an Israeli Cold Storage Facility Project Overview BESS for Industrial TOU Arbitrage in Israel shows how a

Stable Power for Corporate Operations — BESS for Headquarters Microgrid in Nigeria

Stable Power for Corporate Operations — in Nigeria Project Overview BESS for Headquarters Microgrid in Nigeria demonstrates how a 250kW/522kWh cabinet battery energy storage system