News

DC-Coupled vs. AC-Coupled Energy Storage Systems

- October 11, 2025

In today’s rapidly expanding solar-plus-storage market, system architecture has become a key factor that determines efficiency, cost-effectiveness, and long-term returns. Among the mainstream architectures, DC-coupled and AC-coupled energy storage systems each have distinct advantages in design, energy flow, and application scenarios. Understanding their differences is essential for designing high-performance, future-ready energy solutions.

System Architecture Overview

DC-Coupled Energy Storage Systems

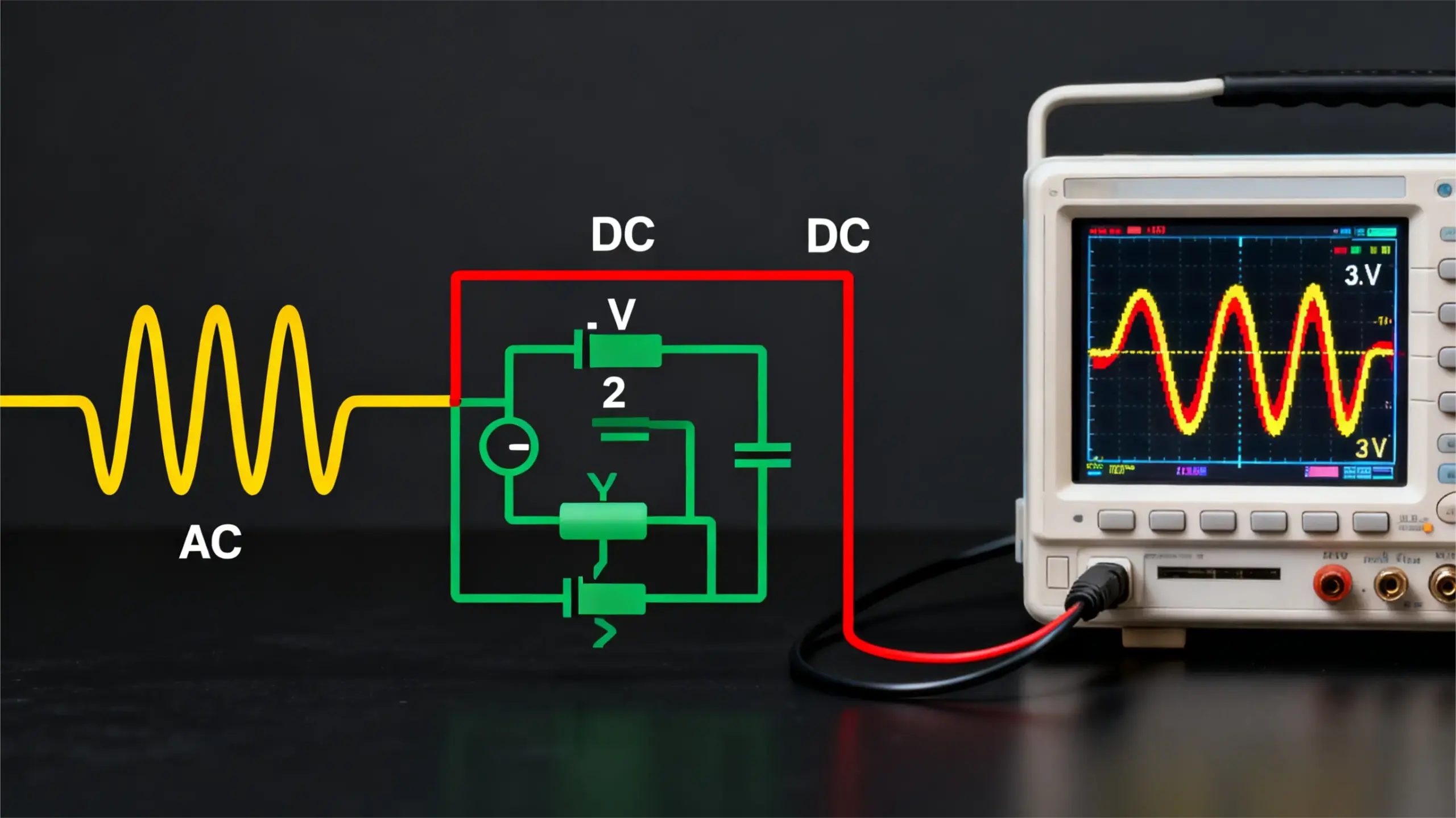

In a DC-coupled system, the photovoltaic (PV) array and the battery share the same DC bus. The PV power is regulated by a DC/DC converter and can directly charge the battery. When power is needed, the stored energy passes through the Power Conversion System (PCS) to be converted from DC to AC, supplying the load or feeding into the grid. With fewer conversion stages, this design delivers higher overall efficiency.

AC-Coupled Energy Storage Systems

In an AC-coupled configuration, the PV system and the battery energy storage system (BESS) operate independently. The PV array outputs AC power through a PV inverter, while the BESS connects to the same AC bus via its own PCS. This allows both systems to exchange energy on the AC side. AC coupling offers excellent flexibility and is particularly suitable for retrofitting existing solar projects with energy storage.

Energy Flow and Efficiency

The energy flow in DC-coupled systems is more direct and streamlined, requiring only one AC conversion for output.

In contrast, AC-coupled systems may involve multiple conversions — from DC to AC, back to DC, and again to AC — leading to additional conversion losses.

In practical operation, DC-coupled systems typically achieve round-trip efficiencies of 92%–96%, while AC-coupled systems range between 88%–92%.

This efficiency gap can translate into an additional 4% energy yield in favor of DC coupling — equivalent to 40 kWh more usable energy per 1,000 kWh cycled.

System Complexity and Cost

From a design perspective, DC-coupled systems require more sophisticated DC/DC control strategies and integrated energy management, but they use fewer hardware components and can reduce initial capital costs.

AC-coupled systems, on the other hand, feature simpler control logic and modular scalability, making them easier to install and maintain. However, because both the PV and the battery systems require independent inverters, total equipment costs are usually slightly higher.

For newly built solar-plus-storage projects, DC coupling generally offers higher efficiency and better ROI.

For retrofit applications where solar systems are already in place, AC coupling is more practical due to its plug-and-play flexibility and shorter deployment time.

Control Strategy and Energy Management

Since DC-coupled systems share a common DC bus between PV and batteries, they rely heavily on intelligent energy management systems (EMS) to coordinate energy distribution and power control with precision.

AC-coupled systems, by contrast, allow the PV inverter and the storage inverter to operate semi-independently, simplifying control and enabling modular system expansion.

FFD POWER’s AI-driven Cloud EMS platform dynamically adapts to both DC and AC architectures, leveraging real-time data on load profiles, PV generation forecasts, and electricity prices. This allows the system to automatically optimize charge-discharge strategies, ensuring maximum safety, efficiency, and economic performance.

Application Scenarios

Each architecture excels in different application contexts:

New commercial and industrial solar-plus-storage projects: DC coupling is preferred for higher energy utilization and faster ROI.

Existing PV system upgrades: AC coupling allows for quick integration without major reconstruction.

Off-grid or microgrid systems: DC coupling offers more precise control of energy flow and higher system stability.

Peak shaving and energy arbitrage projects: AC coupling provides flexibility and independent grid interaction.

Critical power applications (e.g., data centers, hospitals): AC coupling enhances system redundancy and reliability.

FFD POWER’s Tailored Solutions

FFD POWER designs each project based on real operational data, customer objectives, and site characteristics, delivering customized energy storage architectures that balance efficiency and flexibility.

DC-Coupled Solutions: Ideal for integrated solar-plus-storage systems, maximizing energy yield and financial returns through high-efficiency PCS and AI-powered EMS coordination.

AC-Coupled Solutions: Designed for fast, compatible retrofits, enabling existing solar owners to seamlessly integrate storage for enhanced energy control and profitability.

AI Energy Optimization: FFD POWER’s cloud-based AI algorithms predict load, PV output, and price fluctuations in real time, dynamically adjusting operation modes for proactive safety and optimal energy trading.

By combining advanced control with robust system design, FFD POWER empowers customers to move from passive storage to active energy management.

Conclusion

DC-coupled and AC-coupled systems are not competitors but complementary solutions tailored for different project goals.

DC coupling represents the pinnacle of integrated efficiency and energy utilization, while AC coupling offers unmatched adaptability and retrofit convenience.

With AI intelligence and digital energy management, FFD POWER ensures both architectures deliver maximum performance, safety, and long-term value — driving the transition from conventional storage to intelligent, value-driven energy ecosystems.