Remote O&M Visibility for Industrial Sites —— in Nigeria

Project Overview

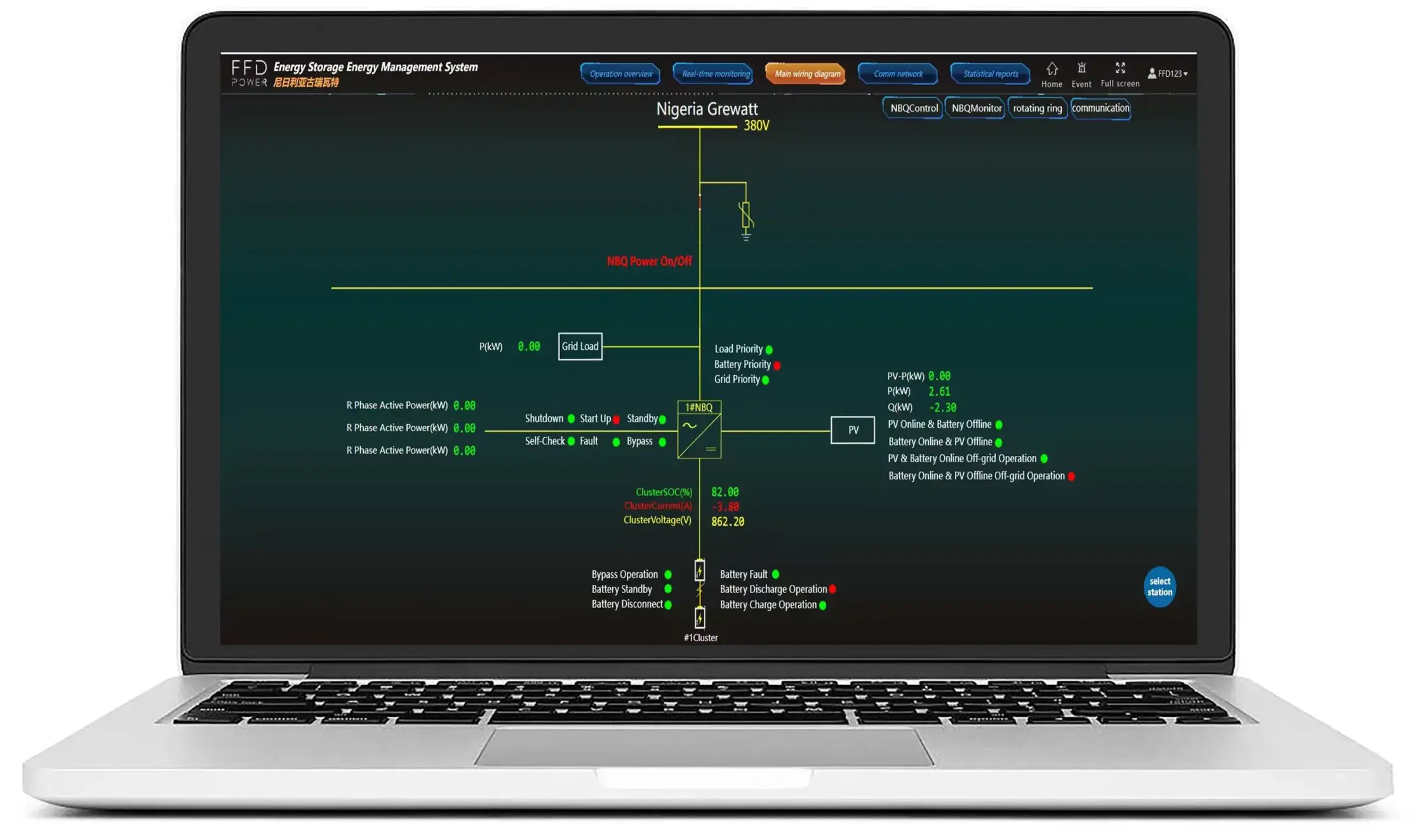

BESS for Remote PCS Monitoring in Nigeria enables operators to track PCS operating status, alarms, and key performance telemetry in real time, helping a small factory reduce troubleshooting time and avoid unnecessary site interventions. By combining a 100kW/261kWh BESS plus hybrid inverter configuration with monitoring-oriented EMS functions, the project improves day-to-day O&M visibility and supports faster, evidence-based maintenance decisions.

Project Background

In many industrial environments, energy assets are expected to operate continuously while on-site technical resources are limited. When the site is remote, access-controlled, or operating under tight production schedules, even a minor PCS trip or auxiliary fault can create extended downtime if the root cause cannot be identified quickly. Under hot, dusty, and humid conditions, intermittent events may be difficult to reproduce on demand—making structured alarms, event records, and trend data essential for reliable operations.

Project Challenge

- Limited on-site troubleshooting windows: faults must be diagnosed with minimal onsite inspection and fewer repeat visits.

- Need for clear PCS status visibility: operators require run/stop state, fault codes, and operating indicators that are easy to interpret.

- Harsh ambient and auxiliary risks: thermal stress and auxiliary component anomalies must be detected early and escalated correctly.

FFD POWER Solution

FFD POWER delivered a monitoring-first all-in-one BESS plus inverter configuration integrated with an EMS layer dedicated to status acquisition, alarm management, and event logging. The system consolidates PCS telemetry and site-level signals into a single operational view, allowing O&M teams to verify system state, pinpoint recurring trip patterns, and plan targeted maintenance actions.

System Specifications

- BESS POWER : 100 KW

- BESS capacity : 261 KWH

- System type : All-in-One BESS Configuration

- Primary function : Site monitoring + PCS running status monitoring

- Architecture: EMS with alarm & event logging for O&M visibility

Operational Logic: Monitoring-First O&M Workflow

The core value lies in how the EMS turns raw signals into actionable operational insight:

- PCS Status Polling: continuously tracks run/stop state, operating mode, key electrical indicators, and PCS fault codes.

- Environmental & Auxiliary Monitoring: watches cabinet temperature and auxiliary health indicators to flag abnormal trends early.

- Alarm Prioritization: maps thresholds and fault categories into graded alarms (information / warning / critical) to reduce alarm fatigue.

- Event Logging: records timestamped transitions (start/stop/trip/reset), alarm histories, and key changes for root-cause analysis.

- Remote Diagnostic Support: enables O&M teams to confirm real-time state, identify recurring issues, and schedule targeted service visits.