News

Microgrid Energy Storage System (Microgrid BESS): How Hybrid Microgrids Deliver Uptime and Economics

- February 3, 2026

A microgrid energy storage system (microgrid BESS with EMS) is the battery-and-control layer inside a microgrid—a localized power system that can operate either grid-connected or islanded, typically coordinating PV, a diesel genset, and the utility grid—to make the whole site dispatchable, stable, and continuity-ready. In other words, it’s the part that lets the microgrid run smoothly no matter which power source is available, keep voltage/frequency under control, and switch or ride through disturbances without power interruption.

What a Microgrid Energy Storage System Includes

A practical microgrid energy storage system is a control stack, not “just a battery”:

- BESS (battery):energy buffer + fast power response

- PCS/inverter:grid-forming / grid-following control capability depending on design

- Microgrid EMS/controller:dispatch logic coordinating grid, PV, genset, and BESS

- Switching & protection:ATS/STS strategy, relays, metering; often required for continuity goals

In real projects (especially weak grids or limited grid access), the BESS is the component that provides the headroom to keep the AC bus stable and controllable.

Why BESS Must Be There in Hybrid Microgrids

PV + BESS: PV uptime during grid problems (high-level, but real)

In many deployments—especially legacy AC-coupled PV—PV output depends on a stable voltage/frequency reference. When the grid is unstable or disappears, PV may curtail or trip. The result is simple: grid trouble can become PV downtime.

A microgrid with BESS + controller is designed so the AC bus stays within acceptable limits, making PV usable through grid events rather than “installed but unavailable.”

Diesel + BESS: minimum-loading discipline and the genset operating sweet spot

Diesel gensets are not happy running light or swinging hard. In practice, many operators target a healthier band where fuel efficiency is better—often around ~70% of nominal power (project-specific, but directionally consistent).

BESS + EMS enables that behavior by shaping net load seen by the genset:

- chargewhen the site load is too low (avoid inefficient low-load operation)

- dischargeduring peaks/steps (avoid overload and reduce transient stress)

This is the core reason diesel hybrid microgrids use batteries even when a genset already exists: control of operating conditions, not just backup energy.

Weak-grid / limited-grid access: EMS + BESS is the dispatch engine

When grid quality is poor or grid access is constrained, value comes from dispatch:

- stabilize voltage/frequency during disturbances

- manage peaks and source priority

- maintain SOC reserve for continuity policy

This is where a microgrid becomes an engineered system rather than a collection of assets.

How Hybrid Microgrid EMS Dispatch Works (Rule-Based Logic That Produces ROI)

A hybrid microgrid EMS can use optimization, rule-based control, or both. For many industrial sites, rule-based dispatch is easier to validate, operate, and maintain.

Practical rule set (high level)

- Grid stable:prioritize PV, use BESS for smoothing/peak shaving and SOC control, keep genset off unless required.

- Grid weak/unreliable:BESS stabilizes the bus; PV stays online if reference is maintained; start genset only for sustained deficit or when SOC hits the reserve threshold.

- Diesel-hybrid mode:target an efficient genset band (often near ~70% nominal when appropriate); charge BESS at low load, discharge during peaks/steps.

- Reserve policy:protect SOC reserve for ride-through and critical loads before economics.

This dispatch discipline is where ROI typically comes from: stable operation, fewer PV trips, lower fuel burn, and less downtime risk.

Seamless Switching: Backup vs Continuity (Numbers That Matter)

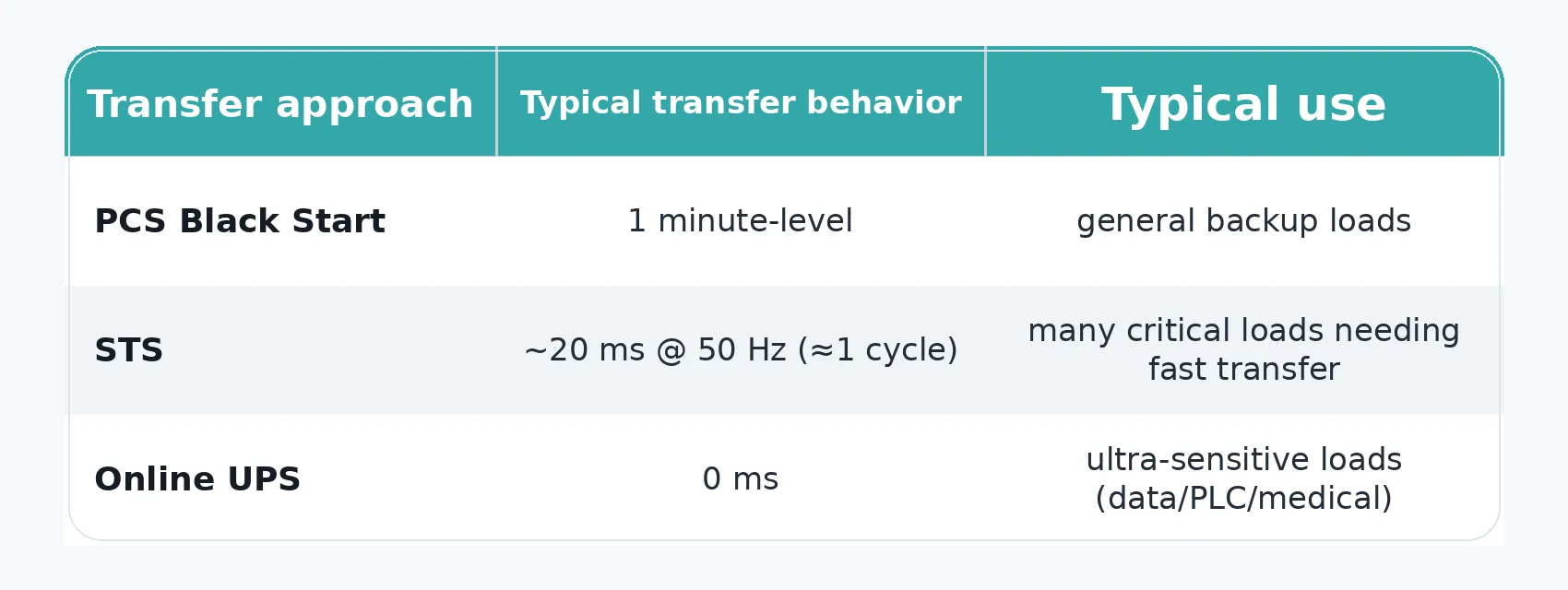

Not every site needs “zero interruption,” but buyers should understand the ladder:

The right approach is usually load-segmented: critical loads get fast/zero-break continuity; the rest can accept slower backup.

Sizing: The Misconception That Breaks Microgrid Designs

A common misconception is: “If my load is X kW, I should size BESS power at X kW.”

That often fails in industrial reality because:

- power factor (PF) means kW ≠ kVA

- inductive loads(motors, compressors, pumps) create steps/inrush

- microgrids need control headroomfor bus stability

Practical principle: size BESS power with redundancy/headroom, not perfect matching.

FFD POWER Solution Introduction: 500 kW / 1044 kWh Fully Hybrid Microgrid (400 V)

FFD POWER’s typical microgrid offering is a fully hybrid template designed for sites that need both economic dispatch and continuity across multiple sources.

Reference configuration

- Type:Grid + PV + Genset + BESS (fully hybrid)

- Scale:500 kW / 1044 kWh

- AC bus:400 V

- Integration elements (when required):Isolation transformer, STS for critical-load fast transfer (20 ms)

Alternative Continuity options in this configuration

- Online UPS (0 ms)as the solution class for the most sensitive loads (e.g., data centers, PLC control production lines, medical equipment) — often treated as a different continuity tier, not a replacement for a hybrid microgrid

Recommended Reads

- Microgrid battery sizing (kW/kWh + PF + inductive loads)

- Diesel hybrid microgrid with BESS (minimum loading + sweet spotstrategy)

- Solar microgrid battery storage (PV uptime, AC vs DC couple)

- Microgrid backup vs seamless transition (STS vs online UPS)

- Hybrid microgrid EMS dispatch logic (reserve + priorities)

- FFD POWER solution example page

FAQ

What is a microgrid energy storage system?

A system combining BESS, PCS, and EMS/controller to stabilize the site bus and dispatch grid/PV/genset/BESS for reliability and economic performance.

How fast can transfer be in a microgrid?

Depends on design: ATS is seconds-level, STS can be ~20 ms at 50 Hz, and online UPS is 0 ms for ultra-sensitive loads.

Why not size BESS power equal to load?

Because PF, inductive loads, and stability margin often require kVA/transient headroom beyond steady-state kW.