News

Understanding the Differences Between Series and Parallel Connections in Energy Storage Systems

- October 28, 2025

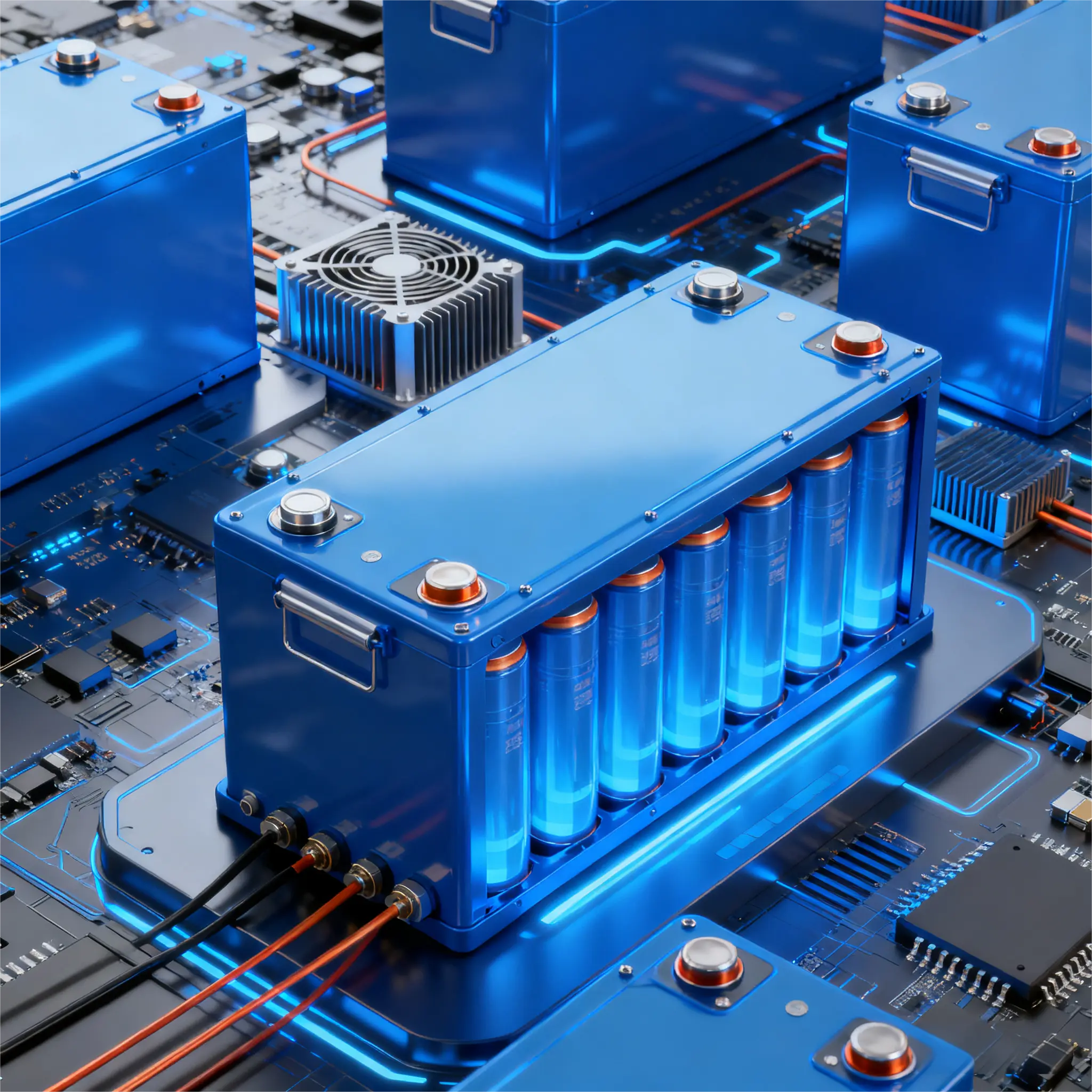

In every energy storage system (ESS), how batteries are connected—in series or in parallel—plays a critical role in determining system performance, safety, and scalability.

This fundamental configuration choice directly affects voltage, current, capacity, and overall reliability.

Understanding the difference between the two is essential for designing efficient and safe energy storage systems.

What Is a Series Connection?

In a series configuration, battery cells are connected end-to-end, so that the voltage adds up while the current remains the same.

For example, connecting ten 48V battery modules in series results in a total of 480V system voltage.

Series connections are primarily used to increase the overall system voltage, enabling compatibility with high-power PCS (Power Conversion Systems) or inverters.

This structure is commonly found in industrial, commercial, and grid-scale ESS where high-voltage operation is essential for efficiency.

What Is a Parallel Connection?

In a parallel configuration, all battery modules’ positive terminals are connected together, and all negative terminals are connected together.

This keeps the voltage constant while the current (and capacity) adds up.

For example, connecting four 48V/100Ah batteries in parallel keeps the voltage at 48V but increases the total capacity to 400Ah.

Parallel connections are ideal for increasing system capacity (energy), providing longer discharge durations and improved load stability.

They are commonly used in residential ESS, low-voltage microgrids, and systems where flexibility and scalability are key.

Key Technical Differences Between Series and Parallel Connections

(1) Voltage and Current Behavior

Series: Voltage increases with each additional unit; current remains constant.

Parallel: Current increases with each additional unit; voltage remains constant.

(2) Design Objective

Series connections are chosen to achieve high voltage for efficient power conversion.

Parallel connections are used to expand system capacity and extend operating time.

(3) Control and Monitoring Complexity

Series systems require precise voltage balancing and protection against overcharge or over-discharge of individual cells.

Parallel systems require current balancing to prevent uneven load sharing and overcurrent risks.

(4) Safety Considerations

Series configurations are more sensitive to “weak cell effects,” where one degraded cell can limit the whole string.

Parallel configurations face potential backflow currents if voltage differences occur between strings.

(5) Expansion and Maintenance

Series structures are ideal for voltage scaling.

Parallel setups allow capacity expansion and easier module replacement.

The Hybrid Series-Parallel Architecture in Modern ESS

In real-world energy storage systems, designers rarely rely on purely series or purely parallel connections.

Instead, most modern ESS adopt a hybrid configuration — combining both.

Typically, multiple cells are connected in series to form a module, and several modules are connected in parallel to create a battery rack or cluster.

This design allows:

High-voltage operation for efficiency,

Large capacity for energy duration,

Flexible scalability for project-specific needs.

FFDPOWER’s Galaxy Series adopts this modular hybrid design, managed by an advanced BMS that ensures:

Real-time voltage balancing across series modules,

Dynamic current sharing among parallel clusters,

Automatic fault isolation and redundancy protection.

The result is a high-performance, safe, and intelligent energy storage system designed for long-term stability.

Technical Challenges and Key Control Strategies

Voltage and Current Balancing

Uneven voltage in series connections may lead to cell degradation, while current imbalance in parallel systems can cause overheating.

AI-enabled BMS plays a critical role by dynamically monitoring each module and maintaining electrical equilibrium in real time.

Fault Isolation

In series systems, bypass circuits or isolating switches can prevent a single-cell fault from affecting the entire string.

In parallel systems, reverse current protection devices prevent energy backflow between strings.

Module Consistency Management

Uniformity in internal resistance, capacity, and temperature response is essential.

FFDPOWER ensures this through cell-level screening, precise matching, and smart calibration during production.

Recommended Applications for Each Connection Type

For High-Voltage Industrial Systems

Use series-dominant hybrid configurations — ideal for large factories, commercial facilities, and utility-scale ESS where high voltage improves PCS efficiency.

For Residential and Low-Voltage Systems

Use parallel-dominant designs — easier to expand, safer to maintain, and ideal for home and small business ESS.

For Off-Grid and Microgrid Applications

Use balanced series-parallel systems — combining high voltage for inverter performance and large capacity for long-duration autonomy.

For Mobile or Portable Energy Systems

Use parallel setups — offering stable output, modularity, and simplified control.

Conclusion: Balancing Efficiency, Capacity, and Safety

The choice between series and parallel connection is more than an electrical decision — it represents a system design philosophy:

-

Series for efficiency and power,

-

Parallel for capacity and redundancy,

-

Hybrid for balance and optimization.

At FFD POWER, we integrate advanced BMS and AI optimization algorithms to combine the strengths of both approaches.

Our intelligent architecture ensures high voltage stability, current balance, and proactive safety, delivering storage systems that are smarter, safer, and more valuable — powering the energy future with confidence.