Project Overview

To strengthen operational competitiveness under time-of-use tariffs, FFD POWER deployed a modular BESS solution for a beverage manufacturing facility in Israel. This project shows how a BESS lowers electricity costs and increases energy flexibility by charging during low-tariff valley periods (and with surplus onsite PV) and discharging during peak-tariff hours—enabling time-of-use arbitrage, peak shaving, and higher renewable self-consumption.

Project Background

Beverage production lines are electricity-intensive and highly sensitive to short-term load swings from compressors, chillers, and packaging equipment. With escalating grid tariffs and demand-charge exposure, the factory required a site-level energy buffer that could respond quickly to load changes, capture low-cost energy, and coordinate with existing PV generation to reduce curtailment and maximize economic returns.

Project Challenge

- Cost Volatility: Time-of-use pricing and demand charges increased operating expenses and made energy planning difficult.

- Dynamic Industrial Loads: Fast-changing production loads required rapid power response and stable grid interaction.

- PV Utilization: Surplus PV during low-demand hours risked curtailment without storage to absorb and shift energy.

FFD POWER Solution

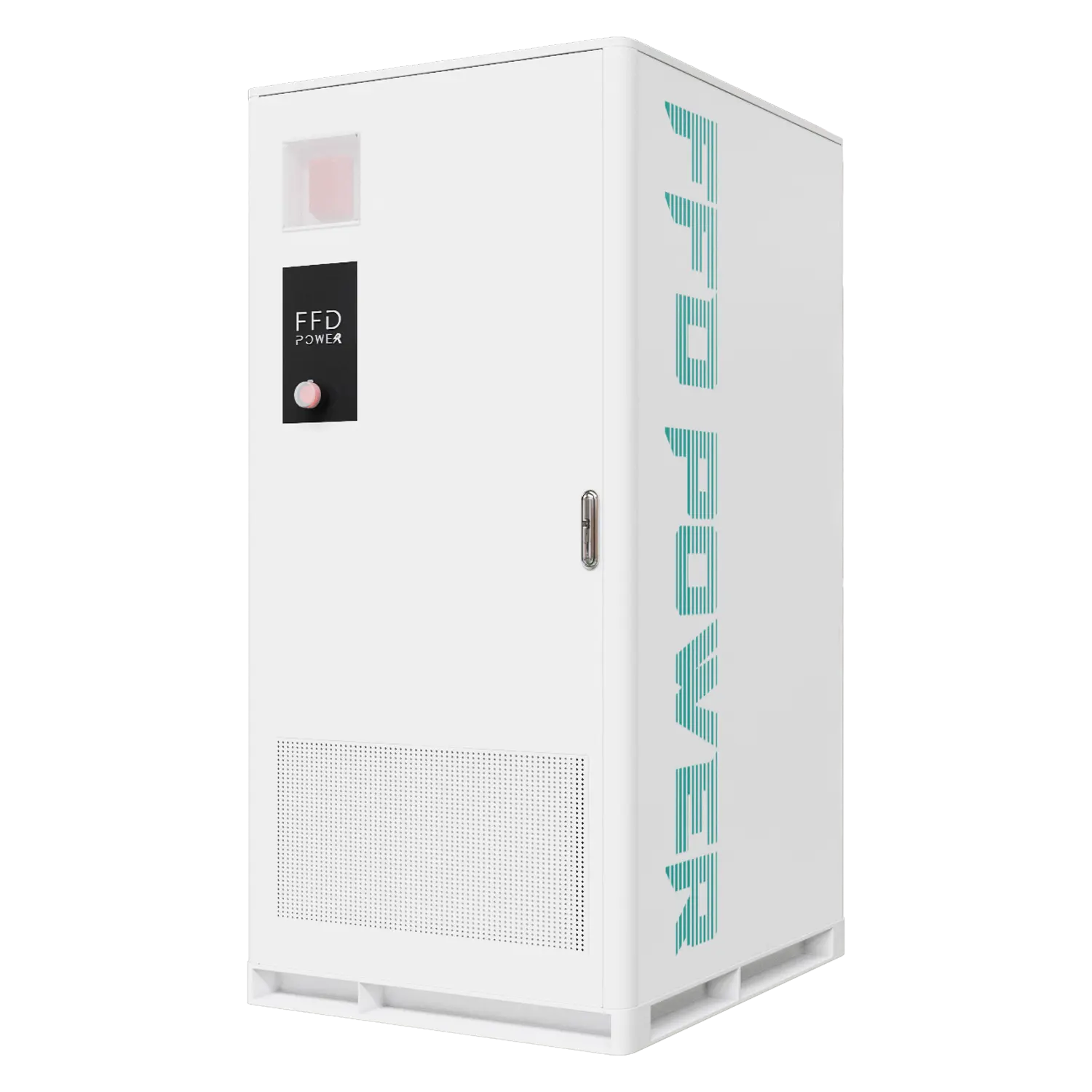

FFD POWER implemented a scalable LFP battery system using 22 units of Galaxy 233L-AIO-2H. The solution combines pre-integrated hardware with an intelligent EMS that monitors real-time tariffs and site load, and dynamically optimizes charge/discharge commands based on SoC, PV forecasts, and tariff signals. Seamless on/off-grid switching and rapid transient response support industrial reliability while maximizing time-of-use arbitrage value.

System Specifications

- PV installed : Existing onsite PV, coordinated via EMS for surplus capture and curtailment reduction

- BESS POWER : 2.2 MW

- BESS capacity : 5.1 MWH

- Product used : Galaxy 233L-AIO-2H * 22 units (LFP, 2-hour configuration)

- Architecture: Modular, pre-integrated BESS with intelligent EMS for peak shaving, valley filling, and PV self-consumption optimization

Operational Logic: TOU Arbitrage and Peak Shaving

The system uses an EMS to optimize time-of-use arbitrage, peak shaving, and PV self-consumption through dynamic charge/discharge scheduling:

- Charge on Low/Negative Tariffs & PV Surplus: The BESS charges during valley or negative-price windows and absorbs surplus PV generation to prevent curtailment and increase self-consumption.

- Discharge During Peak Tariffs: Stored energy is released during high-tariff periods (often evening peaks) to reduce grid import and lower electricity bills.

- Peak Shaving for Demand-Charge Reduction: The EMS tracks site load in real time and dispatches power to shave peaks, smoothing grid interaction and reducing demand charges